Impact on Supply Chain post COVID-19

- adhiraj thote

- Aug 17, 2020

- 3 min read

“The supply chain stuff is really tricky.” ~Elon Musk

Didn’t you ever wonder why is it taking so long for the grocery store to replenish the stock? Didn’t you hear a constant buzz about the supply chain in this COVID scenario? Ever wondered how stacking up stuff would affect the Supply Chain and indirectly us? And Yup! Will we get our delivery on time? Let’s see!

For That, we should know how this Pandemic will affect the current supply chain?

What is the impact on the current Supply Chain?

As a result of Lockdowns, closed airspaces, and borders, COVID19 has disrupted the economies of developing as well as developed countries. In particular, because of these barriers, the Global Supply chain is under a significant strain. Its impact on Supply Chain, in any case, will extend well into next year:

Delivery delays – Because of the Supply Chain dynamics alone, waves of stock-outs, order deployment, inventory, and storage problems would already be surfacing in the industries.

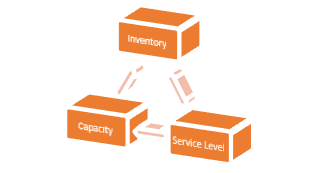

Financial performance/cost performance- if the world got stuck with a financial crisis it is going to be threatened by the triangle of demand

volatility, which means when you get volatile demand there is no other way but to link to higher inventory costs or higher capacity cost or compromise in service level. So, one should expect these rippling effects consequences in the supply chain worldwide.

Safety- Organizations will consider Safety as the first priority and the “new normal” will actually be the operations with advanced safety measures.

But what can be done to avoid these consequences? The answer is Building a Resilient Supply Chain!

How to build a resilient Supply Chain?

A Resilient Supply Chain is one that has the capability to bounce back after major disruptions. Harvard business review in one of its articles says it can be done in three main ways: increasing Redundancy, allowing flexibility, alteration in corporate culture.

1. Increasing Redundancy- Redundancy here means the organization can hold extra inventory, low capacity utilization, multiple suppliers, etc. By

implementing Redundancy Organizations get a room for continuing operations even after disruptions, but at a risk of high cost and quality comptonization. Admired Just in Time (JIT) inventory strategy used by Toyota would be of less use in such disruptions and should be plugged-in the “Business as usual” scenario.

2. Flexibility- When a Company built a flexible supply chain it can handle both big disruptions and even demand variations. To build a flexible supply chain, the organization should implement standardized processes, should have a deep and trustful relationship with suppliers, if not have multiple groups of suppliers. Moreover, Group Technology would also be a great help in building a flexible supply chain that uses a coding system to group similar problems together.

3. Corporate Culture- Organizations should have a continuous communication among themselves, distributed power among employees, for example, Toyota- assembly line workers have had full control over their machines as such that they can shut the production line just by pushing a special alarm button if something goes wrong.

Areas to work on

Inventory Visibility - Organizations can us technologies like Blockchain to have more visibility in supply chains and also to build trustful relationships with their Suppliers. Syncron an after-sales solutions organization has devised a method that how actually blockchain can be used to have clear visibility of inventory in the supply chain.

Keeping a track of your supplier- Companies should know where actually their suppliers are based and how does the raw materials actually get delivered so that they have some time to devise a plan to mitigate the supply chain in major disruptions.

Safety- Considering the current COVID-19 scenario, organizations has to build safety measures considering their strategy to supply Chain and also following the social distancing norms.

Conclusion

So, yes if the organizations got successful in building a resilient Supply Chain, then we can get our product on time and with safety.

How Important it is for a consumer to know about supply Chain of the product he/she is buying? Comment down below. Any organization’s Supply Chain you are interested in?

Comments